Application of intelligent screwdriver on non-standard products

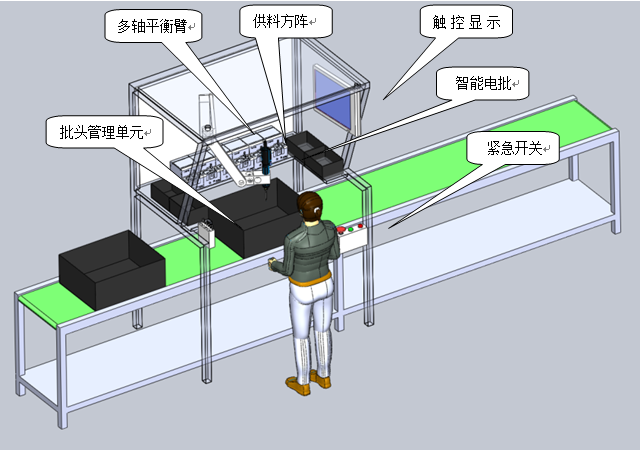

The application of intelligent screwdrivers to non-standard products The term flexible production has become popular after the concept of Industry 4.0. In the past, the manufacturing industry gave the impression that every machine was doing repeated work every day and every hour. But after the concept of flexible production line appeared, people began to pursue a flexible production line that can undertake multiple task modes. Achieving such a production mode can not only save costs effectively, but also greatly improve the production efficiency without letting a product occupy a production line. However, it means that it is difficult to make machinery that once only did repetitive actions become "flexible" in modern technology.

In our daily life, many products are produced according to standard specifications and models. However, with the rise of intelligent manufacturing, people begin to pay attention to personal customization, which is no longer the pursuit of people. Many people are very willing to accept products designed according to their own personality and appearance. Many manufacturers' core goals have also changed from product centered to service centered production methods, This is also bound to be the path of future manufacturing development. Therefore, no matter what kind of occasions in the production process, a multi-purpose machine is a required element.

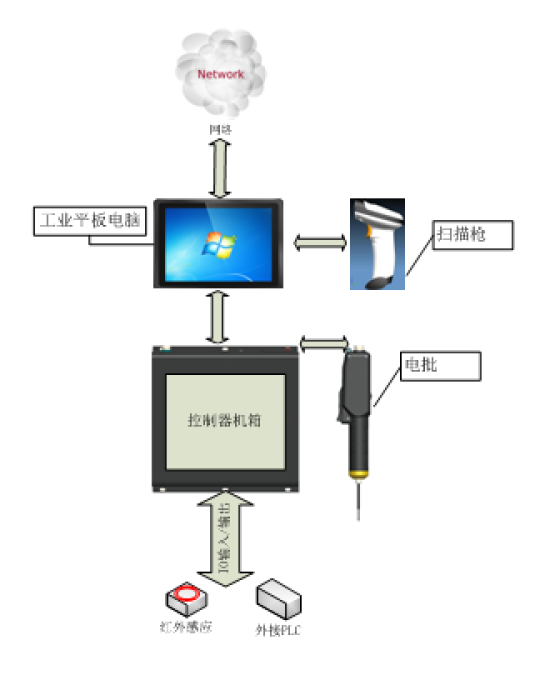

The intelligent screwdriver can perfectly meet the requirements of flexible assembly in assembly. Its main principle is that according to the data stored in the task, and then according to the programming, it can achieve different speeds at different places with different torsion, different turns, and switching tasks at any time to tighten different screws. This feature perfectly meets the requirements of the flexible assembly line.

In addition, general smart screwdrivers can record the tightening data for traceability, so that engineers can judge whether the products produced meet the product quality requirements based on these data. Relevant data analysts can also analyze which supplier's raw materials are more cost-effective based on the torque and turning angle of the screws. It can be said that from the source to the end, there is a lot of cost left for the manufacturer.

In order to combine the development of intelligent manufacturing, the intelligent screwdriver can also be connected to Ethernet, and the controller can modify and adjust the parameters of the intelligent screwdriver, record reading, operation control, etc.

View More >>